While undertaking wear trials during our Base Layer Evaluation between polyester and merino wool fabrics, we received feedback from some field users that the merino wool side of our test harlequin half tops were potentially lacking certain dimensional stability properties and would lose shape retention by developing fabric sag after extended field use. This was primarily observed to occur in the sleeve hem and elbows when the garment sleeves had been rolled up. It was noted that the fabric would once again return to normal dimensions after washing. This was something we were interested to explore further.

In order to verify these reports, we elected to test both stretch and recovery and dimensional stability of our sample polyester and merino wool fabrics. These tests were performed at the RMIT textile testing facility located at the Brunswick Campus in Melbourne, Australia.

During the duration of our wear trial, we received reports of sleeve sag on the merino wool side of the prototype base layers after extended use. This can be observed here on the merino wool side of the garment (grey).

Stretch and Recovery

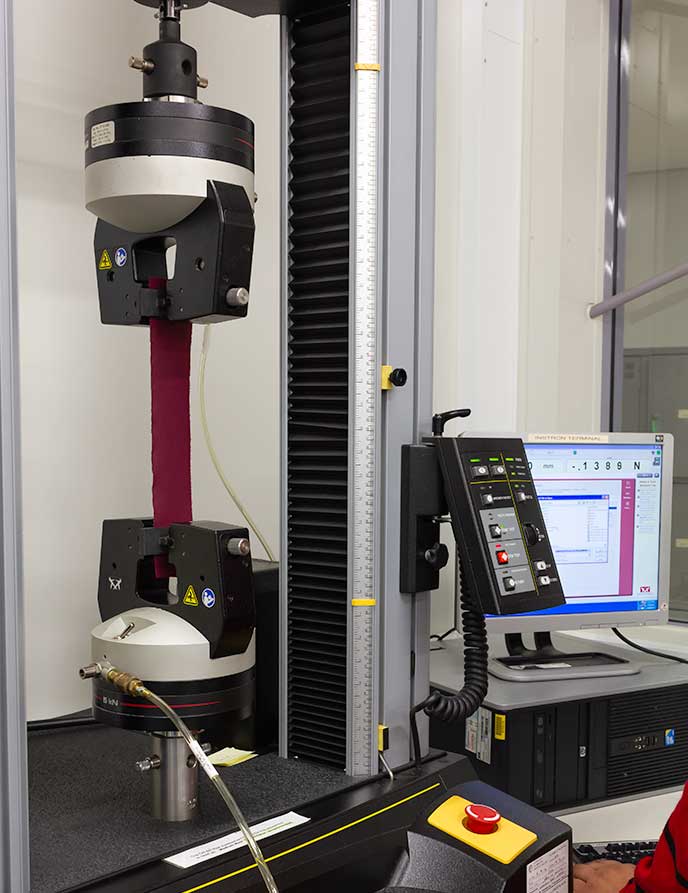

Stretch and recovery can be considered an important factor for base layers, as this fabric quality may allow for the garment to move with the body during motions of climbing, bending, sitting, or flexing of the knees and elbows. The stretch and recovery of our sample fabrics were tested in accordance with the specifications and procedures set out in the standard BS EN14704.1; Determination of the elasticity of fabrics – Strip test, using the Instron Tensile Strength Tester.

The Instron Tensile Strength Tester allows for the measurement of textile strips to determine how the fabric will react when forces are applied in tension.

Stretch and Recovery – Results

During this series of laboratory testing, we compared the identical fabrics used in our prototype field test garments:

- Wool – Sample 1 (field trial fabric)

- 100% merino wool (18.5 micron)

- 135 gsm

- Staple fibre

- Single jersey knitted construction

- Polyester – Sample 2 (field trial fabric)

- 100% polyester

- 130 gsm

- Continuous filament

- Interlock knitted construction

We also included another heavier merino wool fabric in this series of tests that was not used in the field trials:

- Wool – Sample 3 (non field trial fabric)

- 100% merino wool (20.5 micron)

- 270 gsm

- Staple fibre

- Single jersey knitted construction

Wool – Sample 1 (135 gsm) Residual Stretch %

| Sample No | Courses | Wales | ||

|---|---|---|---|---|

| after 1 min | after 30 min | after 1 min | after 30 min | |

| 1 | 12 | 2 | 2 | 0 |

| 2 | 15 | 3 | 4 | 0 |

| 3 | 14 | 3 | 5 | 0 |

| 4 | 15 | 3 | 3 | 0 |

| 5 | 12 | 2 | 2 | 0 |

Polyester – Sample 2 (130 gsm) Residual Stretch %

| Sample No | Courses | Wales | ||

|---|---|---|---|---|

| after 1 min | after 30 min | after 1 min | after 30 min | |

| 1 | 1 | 0 | 2 | 0 |

| 2 | 2 | 0 | 3 | 0 |

| 3 | 1 | 0 | 1 | 0 |

| 4 | 2 | 0 | 2 | 0 |

| 5 | 2 | 0 | 1 | 0 |

Wool – Sample 3 (270 gsm) Residual Stretch %

| Sample No | Courses | Wales | ||

|---|---|---|---|---|

| after 1 min | after 30 min | after 1 min | after 30 min | |

| 1 | 1 | 0 | 2 | 0 |

| 2 | 2 | 0 | 3 | 0 |

| 3 | 1 | 0 | 1 | 0 |

| 4 | 2 | 0 | 2 | 0 |

| 5 | 2 | 0 | 1 | 0 |

The laboratory results confirmed what our field testers were experiencing, the 100% merino wool fabric did indeed demonstrate the poorest recovery, particularly along its width (courses). In comparison, the polyester fabric exhibited excellent recovery with the residual stretch returning to zero after 30 minutes both in length (wales) and width (courses).

Although our third trial fabric was also merino wool, it was twice as thick as the merino wool fabric used in our wear trials. This merino wool fabric also exhibited excellent recovery comparable to that of our polyester test fabric, returning to zero residual stretch after 30 minutes. These tests demonstrated that poor fabric resilience may be influenced by multiple factors including fabric weight, fabric thickness, and knit construction.

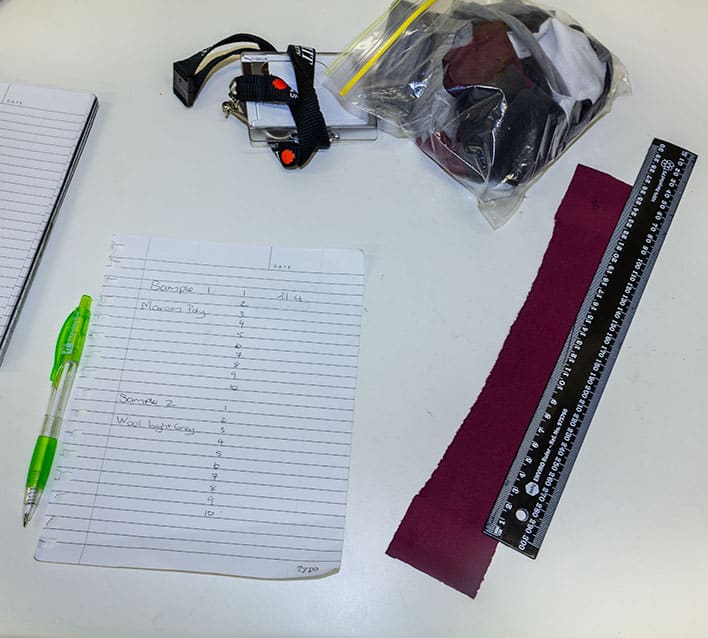

Numerous sample strips of test fabrics are measured on the Instron Tensile Strength Tester under prescribed force to determine their recovery to tension.

Dimensional Stability

The dimensional stability of fabric is an important characteristic to determine whether the fabric can remain stable and keep its shape. Our field testers reported that the merino wool side of our test garments would sag at the sleeve hem and elbow when the sleeves had been rolled up for an extended period, but that the prototype sample would return to its regular shape after washing.

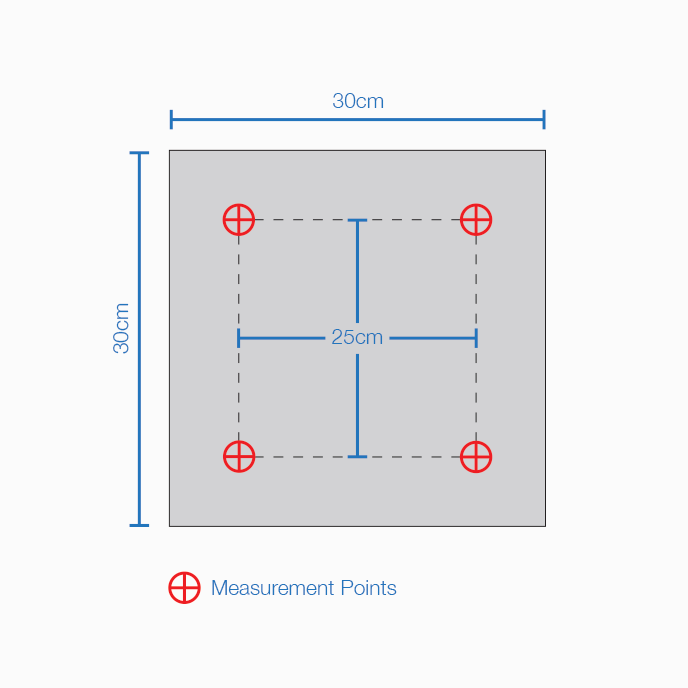

Our sample fabrics were tested in accordance with the specifications and procedures set out in the standard AS 2001.5.1 and the standard for the automatic machine method was used, AS 2001.5.4 to determine dimensional stability after regular laundering.

(Da – Do) / Da

x 100 = % Dc

Where:

Do = Original Dimension

Da = Dimension After Laundering

Dc = Dimensional Change

A negative result (–) will denote a decrease in the dimensions of the sample; a positive result (+) will indicate an increase in the dimensions of the sample. In the above measurements Da = 25cm, the original measurement width and length of the specimen.

Testing dimensional stability to laundering. Fabric samples are cut to specific lengths and measured at precise points according to standard AS 2001.5.4.

Dimensional Stability – Results

The test results revealed the polyester fabric to have excellent dimensional stability with small changes recorded in dimensions. The merino wool fabric produced a greater degree in dimensional change with a slight increase in width and a 4.6% decrease in length. This would explain the field test reports of the merino wool returning to its original shape after washing. Although the merino wool fabric did exhibit less resilience during the stretch and recovery test, it showed more shrinkage in dimensional stability.

Dimensional Stability Test Results

| Merino Wool – sample 1 | Polyester – sample 2 | |||

|---|---|---|---|---|

| Measurement Points | cm | % | cm | % |

| A-B Width | 25.4 | +1.6 | 24.9 | –0.4 |

| B-C Length | 23.8 | –4.8 | 25 | 0.0 |

| C-D Width | 25.2 | +0.8 | 24.7 | –1.2 |

| D-A Length | 23.9 | –4.4 | 25.1 | +0.4 |

| Total Width Change | +0.60 | +1.2 | –0.4 | –0.8 |

| Total Length Change | –2.3 | –4.6 | +0.1 | +0.2 |

Conclusion

In this series of examinations, our test polyester fabric showed to have greater recovery and better dimensional stability. Although our tested merino wool fabric exhibited poor recovery, it was able to regain its shape after washing. Our second merino wool sample that was heavier and thicker than our main merino wool fabric did also exhibit excellent recovery comparable to our test polyester fabric. These have been important revelations to help us achieve our goal of developing the most practical base layer for hunting applications which may exhibit improved recovery and dimensional stability characteristics.

I’m very interested and excited to try your new base layers out. Please email me whenever the go up for sale

Hi Dean, we are also very excited to launch these products. These will be available very soon, please consider signing up to our Newsletter, we will be sending updates to all subscribers.

Will they come in solid colours?

Yes we will have solid and camo 🙂

I’m hanging for these to come out already

Same

Not long now, we’ll have lots of options.