Today merino wool fabrics have gained a strong following amongst outdoor enthusiasts for use as next to skin base layer garments. Traditionally wool has not been used as a next to skin fabric due to its irritating abrasive qualities. Wool fibres are measured in microns, typically regular wool fibres can measure in grades of 30-40 microns with coarser wool being over 40 microns or more. However, the advent of superfine merino, primarily from the merino sheep breed, has changed this. Superfine merino wool generally consists of individual fibres at or below 18.5 microns, these superfine merino fibres are much finer and softer than regular wool and make a merino garment much more pleasant to wear directly against the skin.

The merino sheep breed was originally developed in Spain and prized for its fine wool. It was introduced to Australia in 1797 where selective breeding led to an even finer grade of merino wool being developed. Today Australian merino wool is considered to be some of the finest in the world.

Merino sheep are renowned for their soft fine wool. Australia is the worlds leading producer of merino wool, after many years of selective breeding Australia has developed wool that is considered to be some of the finest in the world. Further information and resources can be found at The Woolmark Company

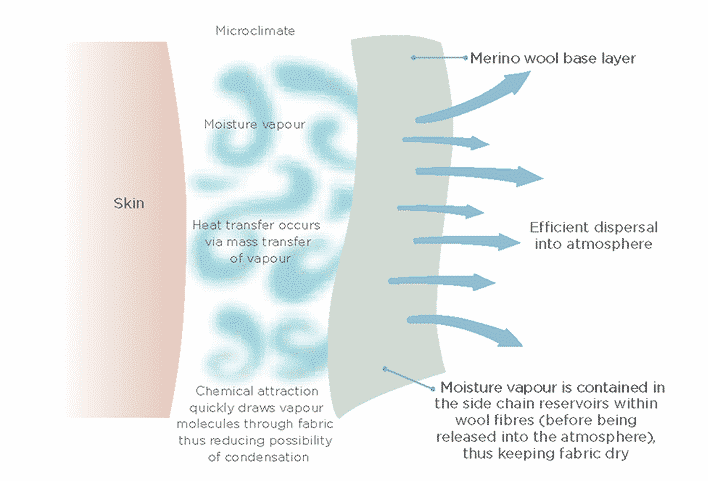

Merino wool microclimate moisture management

The unusual structure of merino wool makes it a unique fibre. Unlike synthetics, which have a uniform composition both internally and externally, merino wool has a unique construction. Its outer surface is hydrophobic (repels moisture), while it’s internal structure is hydrophilic (absorbs moisture). This characteristic allows merino wool to absorb body perspiration and store it within its own structure. Merino wool can occupy up to 35% of its dry weight in moisture vapour and still feel dry to touch, this can positively influence the microclimate on your skin’s surface by locking away perspiration and reducing clamminess.

Another unique property of wool is that as it absorbs moisture internally due to its hydrophilic core, it can actually release heat through a process known as heat of sorption. This phenomenon may also explain why many report that wool feels warmer when wet compared to other fabrics. It can be considered a positive attribute in cold conditions where high energy and increased sweating rate, followed by periods of inactivity can be expected. An example of this is climbing to a high vantage, and then settling in to glass for game.

The ability of wool fibres to store moisture within their physical structure does generally make them slower drying though, particularly when compared to fibres that are totally hydrophobic, such as synthetic polyester. Water evaporates at the same rate, regardless of the textile structure it is contained within. When wetted, the hydrophilic nature of wool means it has more moisture to begin with, thus extending the drying time. It also explains why wool can become heavy when wet.

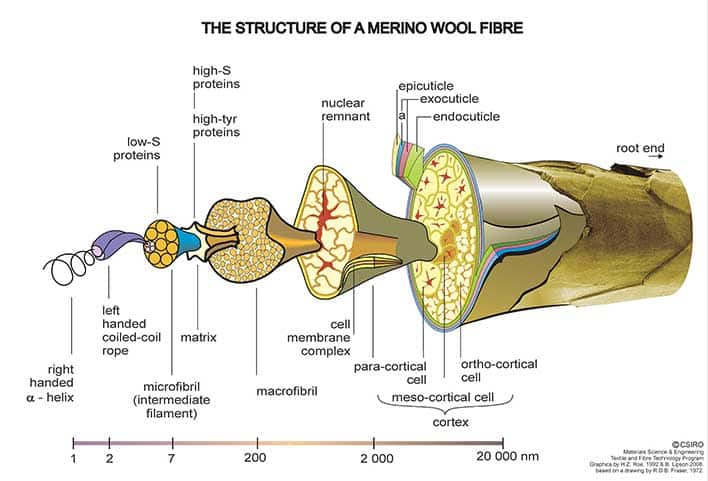

The merino fibre consists of a complex internal structure that can absorb moisture, combined with a scaly external surface that has the ability to repel water. Image by CSIRO Materials Science & Engineering Textile & Fibre Technology Program. Graphics by H.Z Roe 1992 & B. Lipson 2008, based on a drawing by R.D.B Fraser, 1972.

Merino wool odour control

One of the factors that draw many hunters to merino wool base layers over synthetic is their ability to inhibit the build-up of body odours. Sweat itself has no odour, however, if it remains on the skin for a number of hours bacteria develops that can lead to body odour. The merino wool fibre surface is not only hydrophobic but also of a scaly structure. This makes it difficult for microbes to either penetrate or attach onto the fibre surface, providing a poor environment for bacterial growth.

The very outer layer of the epicuticle also contains high concentrations of a unique C21 fatty acid bound to the surface that is linked to antimicrobial properties; while a complex internal chemistry allows it to potentially bind acidic, basic, and sulphurous odours. These are important components of body odour control.

Wool fibres are composed of two types of cell: the internal cells of the cortex and external cuticle cells that form a sheath around the fibre. These cuticle cells (or scales), which overlap like tiles on a roof, make wool unique amongst textile fibres and form a complex physical structure. The exterior surface of merino wool fibres repels moisture as a result of a waxy, hydrocarbon coating that is chemically bound to the surface of each scale.

One negative aspect of merino wool is its reputation for being less durable when compared to synthetic fabrics. This is generally more noticeable in very lightweight merino wool fabrics, with heavier materials generally fairing much better. This can generally be a factor in higher wear areas such as knees, elbows, and cuff hems. Also, areas subjected to abrasion by backpack straps and hip belts may also demonstrate signs of wear, but generally only in repeated and heavy use situations over very long periods of time.

The unique moisture management and superior odour control capabilities of merino wool make this fibre a wise choice for outdoor applications as a next to skin layer. The hunter who understands the benefits and advantages of merino wool may greatly enhance and maximise their comfort levels in the field when wearing base layers made from merino wool fabric.

Mark field testing TUSX prototype merino base layers in the New Zealand mountains. The ability of merino wool to manage moisture while under the physical exertion of hiking with heavy loads, combined with its antimicrobial properties after extended days of use make this fabric a good choice for these conditions.

A good article overall. The ” prickle factor ” starts over 19 microns. Superfine usually refers to wools 17 micron and under but 18 is close. While wool is fantastic for all the reasons you have mentioned you might also like to emphasise that wool is also a renewable resource and completely biodegradable, where synthetic fibre’s from other fabrics account for up to 20% of all microplastics in our oceans.

Thank you TUSX for supporting the wool industry.

Thanks for your comment Adam, you do indeed bring up an important point regarding the biodegradable nature of wool combined with it being renewable. This is an important consideration when compared to many synthetic fibres, which are essentially plastic.

Much of the technical information regarding merino wool was provided to us by CSIRO and The Woolmark Company. Below are micron grades for merino wool used by Australian Wool Innovation and The Woolmark Company:

14.5 micron and finer = Extrafine

14.6 – 16.5 micron = Ultrafine

16.6 – 18.5 = Superfine

18.6 – 20.5 = Fine

20.6 – 22.5 = Medium

22.6 and over = Broad

More information here.

We are happy to support the wool industry 🙂

No worries. Great to see you supporting Aussie farmers and using a superior fibre. 🙂

Thanks mate, we look forward to releasing our base layers and expanding our merino range in the future. Our products will feature 100% Australian merino wool.