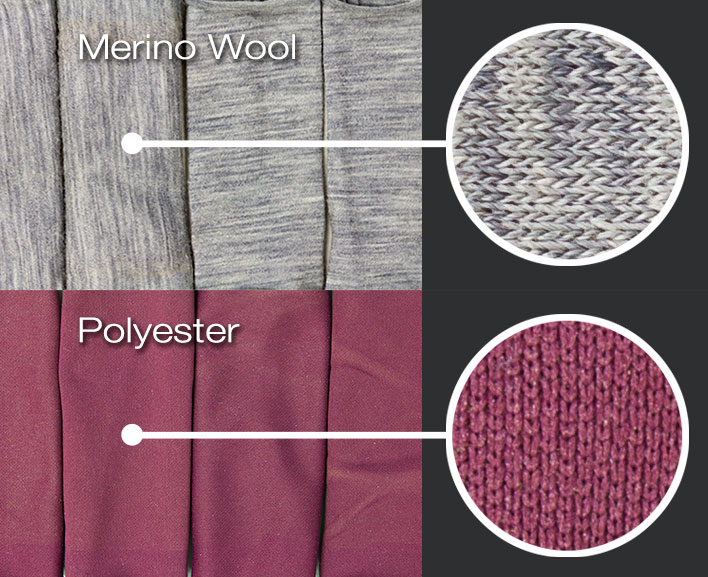

During an extensive wear trial comparing the advantages and disadvantages of merino wool and polyester base layer fabrics, we received feedback from one field user of exaggerated base layer fabric pilling on the polyester side of the prototype harlequin half top. Mark had noticed this to occur on the inner sleeve region as it rubbed against his backpack hip belt while walking.

“While hiking with a trekking pole, changing from hand to hand for equal periods with the other hand rubbing on my pack waist belt. I have noticed slight wear in the form of pilling on the synthetic side while the wool side shows minimal wear.”

This base layer fabric pilling was surprising and unexpected, as polyester has the greater reputation for strength between the two fabrics. We decided to investigate this further in a controlled laboratory environment with the pillbox test method according to the specifications and procedures set out in the ISO Standard 12945-1, performed at Royal Melbourne Institute of Technology Brunswick campus located in Melbourne, Australia..

Mark field testing half merino wool, half polyester prototype base layer to evaluate the differences between these fabrics for next to skin applications.

Extensive base layer fabric pilling was experienced on the polyester side of the prototype half top. The first image illustrates the fabric pilling observed on the polyester side of the prototype base layer, while the merino wool side developed no apparent fabric pilling.

Base layer fabric pilling – laboratory analysis

Pilling formation is a process of entanglement on surface fibres that may occur during wear. To determine the resistance to base layer fabric pilling, specimens are mounted on polyurethane tubes and tumbled randomly within a cork-lined box with other samples of the same fabric. After a specified period of time, the change in appearance is assessed against a rating scale.

- Dense surface fuzzing and/or severe pilling. Pills of varying size and density covering the whole specimen surface.

- Distinct surface fuzzing and/or district fuzzing. Pills of varying sizes and density covering a large proportion of the specimen surface.

- Moderate surface fuzzing and/or partially formed pills. Pills of varying size and density partially covering the specimen surface.

- Slightly surface fuzzing and or partially formed pills.

- No change

Fabric samples are mounted to polyurethane tubes and tumbled for a specified period of time within the cork-lined pillbox.

Base layer fabric pilling – results

The base layer fabric pilling laboratory tests did not correlate with some of the results in the wear trials. Both the merino wool and polyester base layer fabric scored well with grades of 4.5 and 5, this means they both showed little or no fabric pilling with only slight fabric fuzzing present. This result contrasted the wear trial results where the polyester fabric exhibited excessive degrees of fabric pilling.

Fabric Pilling Test Results

| Sample No | Merino Wool | Polyester |

|---|---|---|

| 1 | 5 | 4 |

| 2 | 5 | 4 |

| 3 | 4 | 4 |

| 5 | 4 | 4 |

| Average Result | 4.5 | 4 |

After Mark’s field experience we were expecting to see similar results with the laboratory tests, however, this was not the case with both the merino wool and polyester fabric experiencing similar results.

Conclusion

After consulting some of the senior researchers in the laboratory and showing them images of the wear trial base layer fabric pilling, they have suggested that the polyester filaments may have been breaking and in turn entangling with other broken filaments to eventually form pilling balls on the fabric face. We expect the prototype base layer was rubbing on a fairly abrasive surface during the wear trial.

The pillbox method does not create enough rubbing force to break the polyester filaments, hence it has performed better in the laboratory test compared to the wear trial. Merino wool is a staple fibre and therefore already has loose ends. Even so, it did not pill during Marks field testing. This was a very positive base layer fabric pilling result for merino wool.